Nkọwa

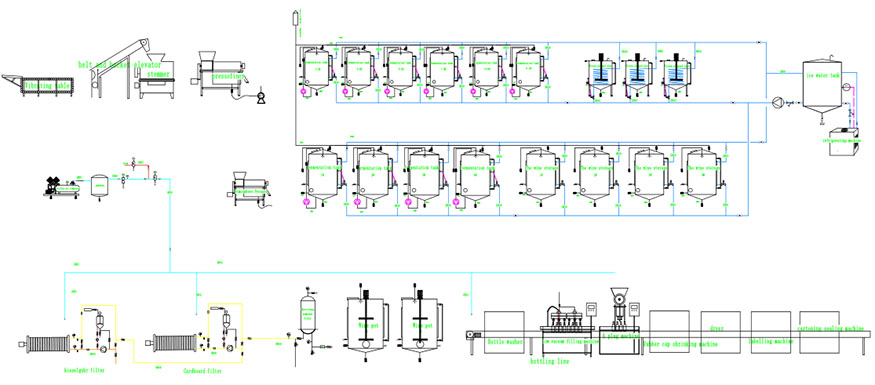

| 1 | Ngwa nhazi tupu emee | Tebụl nhọrọ ịma jijiji akụrụngwa Buli elu Na-emebi emebi crusher Mkpọsa pịa Mpempe eriri afọ nwere ike ibugharị (maka ịpị mmanya) |

| 2 | Akụrụngwa ịgba ụka | tankị gbaa mmanya ọcha ọcha tankị gbaa mmanya uhie uhie tankị nchekwa mmanya tank na-ekpo ọkụ Egwuchara tank |

| 3 | Ngwa distillation | Ngwa distillation Brandy distillation unit |

| 4 | Ngalaba jụrụ oyi | Igwe nju oyi Glycol mmiri mmiri tank |

| 5 | Fsistemu eji eme ihe | Nzacha diatomite Ihe nzacha kaadiboodu Akụrụngwa filtration membrane Mkpa ọkụ efere efere Peel mgbapụta (ụdị ịghasa mgbapụta pomace) |

| 6 | Sistemụ ndochi | Igwe na-asa akwa karama akpaaka Igwe ndochi Nkwụsị Drier Igwe okpu rọba nwere ike ikpo ọkụ Igwe eji akara Igwe akara teepu |

| 7 | Usoro nhicha | Ngalaba CIP |

| 8 | Usoro njikwa | Onye na-ahụ maka PLC maka ịchịkwa okpomọkụ nke tankị |

Ụlọ ọrụ Alston nwere ike chepụta mmanya ahaziri ahazi na usoro ịgba ụka mmanya na mkpụrụ osisi dị ka ihe onye ọrụ chọrọ, gụnyere tankị nchekwa mmanya, tankị na-ekpo ọkụ, tankị na-ese n'elu mmiri, tankị refrigerant, tankị na-ekpo ọkụ, ọkpọ ọkpọ oyi, ikpo okwu, nkeji refrigeration, usoro nchịkwa, usoro nhicha CIP. , wdg Ọ nwere ike izute ihe achọrọ nke usoro mmepụta dị iche iche, dị ka mmanya na-acha ọbara ọbara, mmanya ọcha, mmanya na-egbuke egbuke na mmanya ice.

Iji gboo mkpa nke ndị ahịa, ụlọ ọrụ anyị nwere ike ịnye gị ahịrị mmepụta akpaaka ma ọ bụ ọkara-automci zuru oke dịka ihe ndị ọrụ chọrọ.

1. Usoro ọgwụgwọ tupu: Grape destemming crusher, ịghasa mgbapụta, membrane press, grape vibration separator, scrapter elevator, belt vonveyor.

2. Usoro ịgba ụka: dị ka onye ọrụ chọrọ, ọtụtụ mmanya femneters nwere ike cnfigured ịghọta enzymatic hydrolysis, clarication, oyi impregnation, na-ekpo ọkụ imprenation, mmanya gbaa ụka, apple-mmiri ara ehi gbaa ụka, kefriza na ndị ọzọ usoro, na okpomọkụ na-akpaghị aka na-achịkwa n'oge gbaa ụka. usoro.

3.Sistemụ nzacha: Diatomite filter, cardboard filter, membrane filter.

4. Sistemụ ngwugwu: igwe na-ejuputa ike ndọda, igwe nkwụnye, igwe na-ebelata rọba, igwe na-ede aha na ihe ndị ọzọ.

5. Sistemụ inyeaka: ngalaba CIP, igwe sterilization, mgbapụta mkpanaka, ngalaba refrigeration, sistemu njikwa na ndị ọzọ.

Ndị na-agba mmanya

1. A na-eji fermenti mmanya eme ihe n'ọtụtụ ebe n'ime agba agba nke mmanya uhie, mmanya ọcha, mmanya rose, na mmanya na-egbuke egbuke.

2.Fermenter nhazi jụrụ oyi, kpo oku jaket, dị ka usoro dị iche iche chọrọ, nwere ike nweta enzymatic hydrolysis, nkọwa, oyi impregnation, na-ekpo ọkụ impregnation, mmanya gbaa ụka, pin-mmiri ara ehi gbaa ụka usoro akpaka okpomọkụ akara aka ọrụ.

3. A na-emepụta ngwaahịa niile nke ụlọ ọrụ ahụ na usoro ndị ahịa chọrọ dị ka etiti, whcih nwere ike izute ihe ndị ụlọ ọrụ chọrọ ruo n'ókè kachasị.