Ka anyị hụ nkọwapụta akụrụngwa ebe a na-eme mmanya, nke a bụ 20HL nke a bụ ụgbọ mmiri 3 nwere kettle mash, tank tank, kettle whirlpool na mgbakwunye mmiri ọkụ dị ka ngwakọta.

Site na ebe a na-eme biya a, Nke mbụ, Brewhouse dakọtara na arịrịọ gị.

Ihe ndabere imewe dabere na plato 12-16 iji zute usoro ime biya na biya dị iche iche.Olu na-arụ ọrụ bụ 20HL maka ụgbọ mmiri ọ bụla, mana maka mkpokọta olu bụ ihe dị ka 3200L, maka tankị lauter, dayameta bụ 2000mm, Mgbe wort bụ 16 plato, ego nri bụ 500KG, olu tank na-eji 80%, na akwa akwa. ọkpụrụkpụ bụ 340mm, na ọ bụghị ihe karịrị 350mm, nke ga-emetụta nzacha ọsọ na ime biya arụmọrụ.

Kettle ofe: Nhazi olu kettle dabere na 2320L wort tupu esi esi, yana olu ojiji bụ 65%.N'ihi na itinye uche wort dị elu na North America, ụdị ahụ ga-aba ụba mgbe ị na-esi esi.Iji gbochie ụfụfụ na-ejupụta na kettle n'oge a na-esi nri, anyị na-eji ọrụ mgbasa ozi mmanye na-eme ka ọnụ ọgụgụ nke evaporation dịkwuo mma iji hụ na ikuku evaporation bụ 8-10% ma mee ka ọkụ na-esiwanye ike.Mgbasa mmanye na kettle na-enyere aka ịbawanye evaporation, yana ọnọdụ DMS na ọdịnaya dị n'ime 30PPM, ọ ga-ebelata ikpo ọkụ ọkụ ma hụ na nkwụsi ike nke chroma wort na-ezere mmeghachi omume Maillard wort.

2.Secondly, Lower ike oriri na ebe biya

1.2.1 Sistemụ condensate na kettle: Kettle na-esi esi na-enweta sistemu mgbake ikuku, ọ ga-enyere aka melite mgbake mmiri ma chekwaa mmiri na gas na ebe a na-eme biya.The mgbake mmiri ọkụ okpomọkụ gburugburu 80-85 ℃, na mmiri ọkụ mgbake ike na 300L maka ọ bụla ogbe;Nke ahụ pụtara na ọ ga-azọpụta gas 3m³ kwa ogbe nke mmiri okpomọkụ si 25-85 ℃.

1.2.2 Condersate mmiri si jaket: ọ ga-enye aka dị ukwuu ịzọpụta mmiri na gas na gas uzuoku generator.Naanị iji obere gas kpoo ya wee ghọọ uzuoku mgbe mmiri a na-ekpo ọkụ na-alaghachi na generator ka mmiri mmiri na-ekpo ọkụ dị gburugburu 80 ℃.

1.2.3 Wort ngwa nju oyi: The wort okpomọkụ Exchanger mpaghara gbakọọ site brewing usoro na mechaa jụrụ usoro na 30 nkeji, na mmiri ọkụ okpomọkụ na 85 ℃ mgbe okpomọkụ mgbanwe, okpomọkụ mgbanwe arụmọrụ nke ihe karịrị 95%.Ya mere, anyị ga-ahụ na mgbake ike kachasị na ọnụ ahịa mmepụta dị ala.

3.Support ahaziri iji zute ụdị dị iche ichenke biya

3.1Hops na-agbakwunye ngwaọrụ na kettle ma tinye akọrọ hops akpaka.Dị ka anyị niile maara North America brewer ka hobsite na biya ma tinyekwuo hops iji gbakwunye uto nke hops.

3.2Tubular okpomọkụ Exchanger, Iji kwe ka ebe a na-eme biya mee ka wort dị jụụ tupu ị gbakwunye mgbakwunye whirlpool hop.Enwere igwe mgbanwe okpomoku tubular dị na mpụga iji mee ka wort dị jụụ na-apụ apụ wee laghachi n'ụgbọ ahụ.

4.Fully akpaakaụlọ ime biya

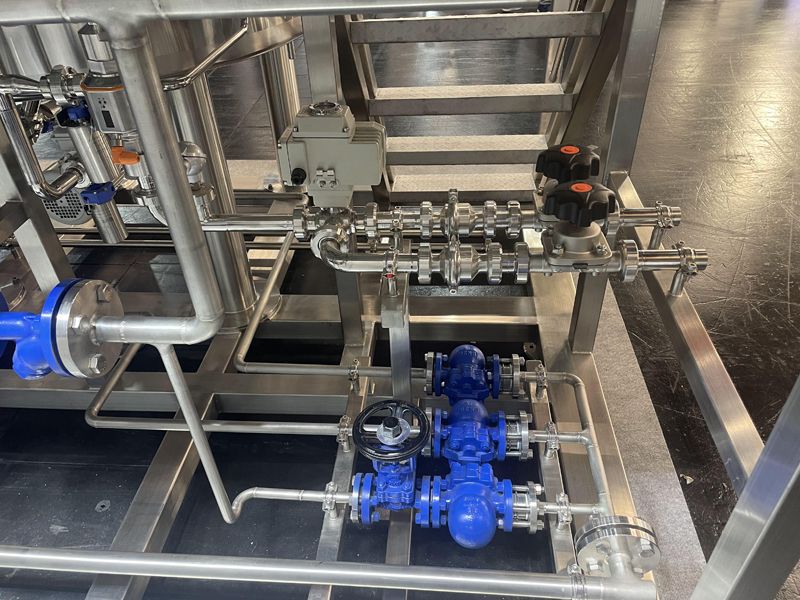

Akpaaka azụmahịaSistemụ ime mmanya ated bụ usoro teknụzụ dị elu nke e mere iji mee ka ọ dị mfe na ịkwalite usoro ịme mmanya n'ọtụtụ azụmaahịa.Usoro mmepụta ihe ga-ejikọta ọrụ ahụ na valvụ pneumatic, valvụ na-achịkwa akpaka na ngbanwe larịị iji nweta ọrụ akpaaka nke ntinye mmiri, nri nri, okpomọkụ, wdg, si otú a na-eme ka mmepụta ihe dị mma ma chekwaa ọrụ na ụlọ ọrụ mmepụta ihe.

Automation nke ọrụ ndị a ọ bụghị nanị na-eme ka biya dị elu dị elu kamakwa na-enye ohere ka ndị na-emepụta mmanya na-arụ ọrụ nke ọma, na-ebelata ihe mkpofu, na ịba ụba uru.

Maka kettle mash,

1.1 Isi ihe bụ pre-masher, usoro ahụ na-abawanye mkpụrụ, na-ebelata ọrụ mashing ma na-eduga na ndepụta iodine dị ala.The ike ịgwakọta usoro na-egbochi mkpokọta grist ma na-ebelata ike chọrọ maka ịgwakọta.N'ihi ya, a na-echebe akpụkpọ anụ na oge ịhịa aka na-adị mkpụmkpụ karị.Enwere ike ịhụ usoro ịhịa aka n'ahụ dum site na iko anya mara mma.Ngalaba ahụ dakọtara kpamkpam CIP.

1.2 Agitator bụ ihe m na-eme nke ọmaSistemụ xing nwere otu mgbasa ozi na-erugharị n'ogo zuru oke nke mash, ọbụlagodi na obere ọsọ.Usoro mgbaba a akọwara na-eme ka nkesa otu ọnọdụ okpomọkụ dị na mash, mmụba na-amịpụta na husks echedoro.

Maka tankị lauter,

1.1 Sistemụ Raker na-ebuli akpaka ma jiri ọka na-akpaghị aka.Ogologo ibu grist na-agbanwe agbanwe na oge nhazi nke miminum, sistemụ anyị na-enye ohere maka ịdị elu grist na-agbanwe agbanwe: A na-ahụta nchacha zuru oke ọ bụghị naanị na ibu grist dị oke elu, kamakwa ọ nwere nnukwu ibu grist dị ala maka biya biya.Nke a na-eme ka usoro ahụ bụrụ ngwá ọrụ dị mma maka ịme biya biya.N'ozuzu, usoro anyị na-enweta oge ntọlite nke na-erughị nkeji 10-20 maka iwepụ mkpụrụ osisi na-ekpochapụ ma na-ehichapụ usoro ahụ, gụnyere imeju ala ụgha.Emere nke a site na teknụzụ draịva ka mma nke usoro mkpochapụ mkpụrụ akụ mefuru na site na nke ọma, ịzọpụta mmiri na-ekpochapụ ala ụgha.

1.2 Sistemụ sparaging dị nso na akwa ọka ma ghara imebi ya maka obere ikuku oxygen na ọ naghị emetụta nzacha ahụ.

1.3 Ogologo nyocha maka nnyefe ọkụ ziri ezi, bọọlụ ihicha okpukpu abụọ ma na-ehicha ụgbọ mmiri na igwe iko, steepụ iji nyere gị aka ịlele n'ime, Net Nche maka nchekwa brewer, oriọna a na-ahụ anya bụ mgbawa - ihe akaebe, ihe mmetụta temp na mgba ọkụ larịị jikọtara njikọ. ka Industrial kabinet iji nweta akpaka version.

Makaọdụ mmiri, Anyị na-eji valvụ Pneumatic, valvụ iwu, nnwale temp, mita eruba ọkwa na-akpaghị aka gbanwee mmiri mmiri, mmiri na-asọpụta na mmiri mmiri site na njikwa njikwa.

Makaahịrị uzuoku, niile njikọ bụ flange iji gbochie uzuoku ntapu na rụrụ ka ogologo oge na-agba ọsọ.Ọzọkwa enwere valvụ maka ebe a arụnyere na-aga azụ eruba nke condensate na igbochi hama mmiri na ọkpọkọ.

Oge nzipu: Jan-23-2024